In applications such as oilseeds processing, the conditioning stage represents a vital step for downstream processes. For example, oilseeds are heated and dried to prescribed temperatures and moisture levels prior to the oil extraction process.

Yet this conditioning stage is also energy-intensive, with steam consumption being the largest utility cost.

Solex's vertical plate conditioning technology provides a more efficient solution to indirect heating and drying of:

Soybean

Rapeseed

Canola

Sunflower

Other types of oilseeds

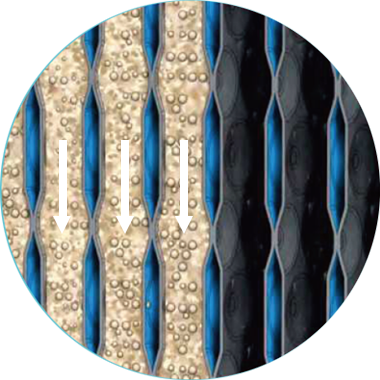

Controlled Product Flow

Free-flowing bulk solids pass slowly downward between a series of vertical hollow heat exchanger plates.

Indirect Heating

Hot water, steam (or waste heat) flow through the plates to heat the material and evaporate moisture from the product.

Mass Flow Technology

The mass flow discharge feeder creates uniform product velocity and regulates product flow rate.

Vertical Design

Bulk solids pass through the unit by gravity, using no moving parts.

Address: Building 53, No.1500 Xinfei Avenue,

Shanghai, China

Tel: +86 27 8789 8319