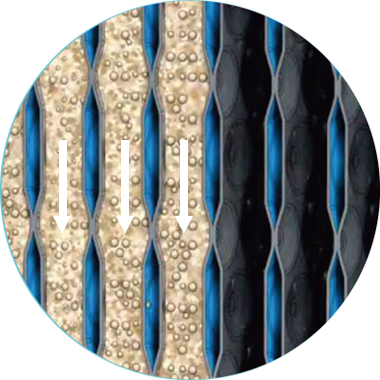

Controlled Product Flow

Free-flowing bulk solids pass slowly downward between a series of vertical hollow heat exchanger plates.

Indirect Plate Cooling

Cooling water flows through the plates to cool the material by conduction.

Mass Flow Technology

The mass flow discharge feeder creates uniform product velocity through the cooler and regulates the product flow rate.

Vertical Design

Address: Building 53, No.1500 Xinfei Avenue,

Shanghai, China

Tel: +86 27 8789 8319