Solex’s heat exchange technology heats bulk solids to uniform temperatures of up to 700°C while using up to 90% less energy, emitting virtually no emissions and offering a significantly smaller installation footprint than traditional methods.

In addition, waste heat from elsewhere in the facility can be captured and reused, improving efficiency and generating even greater cost savings.

Capacity: 100kg/hr to 200,000kg/hr

Heating medium: hot water, steam, thermal oil, indirect air

Product temperature: up to700℃

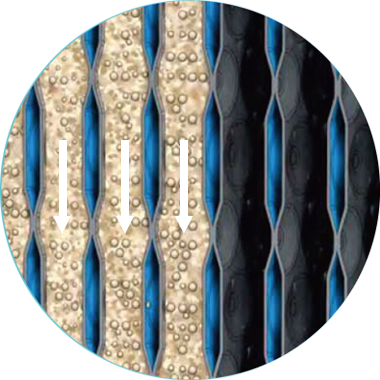

Controlled Product Flow

Free-flowing bulk solids pass slowly downward between a series of vertical hollow heat exchange plates.

Indirect Plate Heating

Steam, hot water, thermal oil or air flow through the plates to heat bulk solids material by conduction.

Mass Flow Technology

The mass flow discharge feeder creates uniform product velocity and regulates product flow rate.

Vertical Design

Address: Building 53, No.1500 Xinfei Avenue,

Shanghai, China

Tel: +86 27 8789 8319