Material Properties Analysis

Material properties of product samples are

tested to determine particle size distribution, pile density, moisture content

and angle of repose. This information helps determine the ideal feeder design

parameters.

Mobility Testing

Flow tests to determine the optimum spacing

among heat transfer plates to ensure that the material does not bridge or

caking and to achieve a free and even flow of material.

Mass Flow Testing

Mass flow testing is used to determine the

flow properties of the material in order to ensure close-phase conveying

(uniform velocity), especially in mass flow feeder.

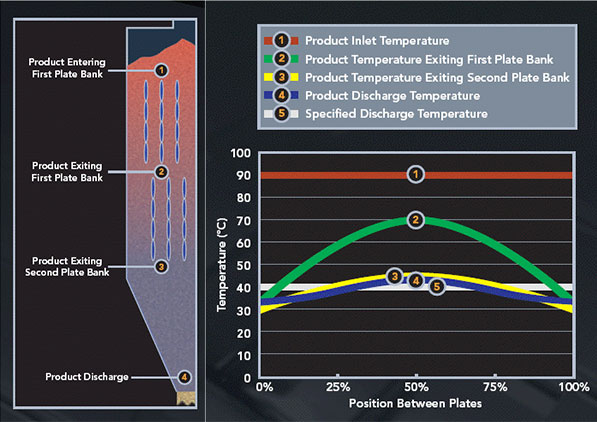

Thermal Performance Analysis

Solex's proprietary thermodynamic modeling

software, ThermaPro, enables accurate prediction of final product temperatures

based on thermal properties and other process parameters.

As a global advocate of plate powder heat

transfer technology, Solex has developed its own unique design software for

calculating and simulating the heat transfer of powdered materials and solid

particles.

This on-site testing is tailored to analyze and validate many of the following for your specific application:

We are on-hand to facilitate, implement and assess the outcomes of this pilot testing and determine the best course of action for full-scale implementation.

As experts in the field of Platecoil heat

exchange technology, we provide a wide range of consulting, equipment supply,

system design and engineering construction services. Our goal is to help you

fully determine the requirements of the project to reduce risk and conduct

project planning, resource allocation, and project scheduling work. We

specialize in:

* Process design and modeling (like energy

and mass balance)

* Material property testing and performance

evaluation

* Equipment design and process sizing

* Process package flow system design

* Piping and instrumentation system design

* Mechanical design and structural evaluation

* Conception, feasibility and detailed

engineering studies

* Techno-economic assessment

Address: Building 53, No.1500 Xinfei Avenue,

Shanghai, China

Tel: +86 27 8789 8319