Unlike conventional drying technologies which blow hot air through the product as both the heat source and the way of removing moisture, Solex's solution uses a combination of advanced platecoil heat exchange technology to provide the heat source and independent sweep air to remove the moisture. This approach greatly reduces air-flow requirements, returning much better efficiencies and improved process control.

Solex's technology heats bulk solids indirectly through conduction, significantly increasing the moisture-carrying capacity of the sweep air for precise temperature and moisture control. Waste heat can be used to power the process, reducing costs and energy consumption even further.

Capacity: 100kg/hr to 200,000kg/hr

Suitable applications: Ideal for grains and oilseeds

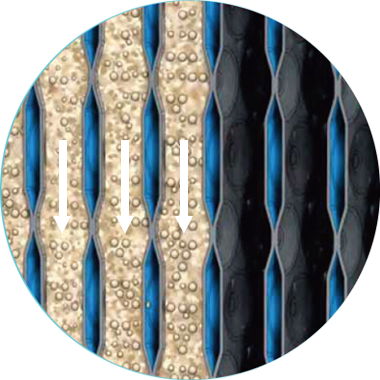

Controlled Product Flow

Free-flowing bulk solids pass slowly downward between a series of vertical hollow heat exchanger plates.

Indirect Heating

Hot water, steam (or waste heat) flow through the plates to heat the material and evaporate moisture from the product.

Sweep Air

Sweep air removes product moisture. A small amount of sweep air is used to remove moisture from the product.

Address: Building 53, No.1500 Xinfei Avenue,

Shanghai, China

Tel: +86 27 8789 8319